Automated Metrology Systems

Acieta brings Industry 4.0 to your quality control process by integrating automated quality inspection and advanced metrology solutions enabling real-time SPC, data traceability, and precision measurements to your production line without compromising throughput.

< 60 seconds

MEASUREMENT TIME PER PART

100%

IN PROCESS INSPECTION

< 1 second

FULL 360° SCANNING

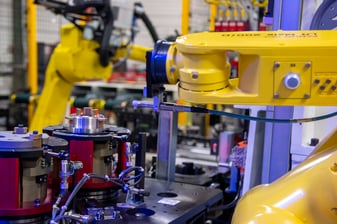

More than metrology equipment, our automated measurement systems bring high-speed, accurate in process inspection directly to your plant floor.

We've helped leaders across automotive, aerospace, medical and general manufacturing leverage the power of automated metrology systems to maintain quality, reduce defects and streamline production.

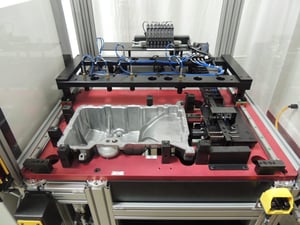

DIMENSIONAL MEASUREMENT

Acieta delivers CMM-grade precision inline, using custom LVDTs, air gages, and 3D systems for fast, repeatable in process inspection of critical dimensions and GD&T features that are built for harsh production environments.

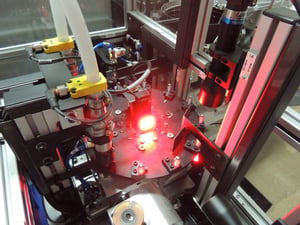

EDDY CURRENT & RESONANCE TEST

Inline non-destructive inspection using eddy current and resonance test systems detect cracks, verify materials and coatings, and confirm heat treatment. All inline and automated to streamline production without sacrificing quality.

3D & 2D VISION INSPECTION SYSTEMS

Automated metrology systems use 2D and 3D vision for full-part inspection, assembly verification, and surface or feature measurement. Flexible, robot, or fixed-mounted systems provide fast, reliable, inline quality control.

LEAK & FLOW TEST SYSTEMS

Automated metrology equipment using pressure and vacuum decay detects leaks, cracks and flow anomalies with high sensitivity. Custom fixtures and adaptable sealing ensure consistent inspection of housings, molded components, and assemblies.

TOOL COMPENSATION GAGE SYSTEMS

By automating tool offsets with automated measurement equipment, these systems provide real-time feedback from gages to CNC machines, enabling accurate part-to-part tool compensation, reducing scrap and supporting predictive maintenance for high-precision machining.

VIRTUAL CONDITION & ATTRIBUTE INSPECTION

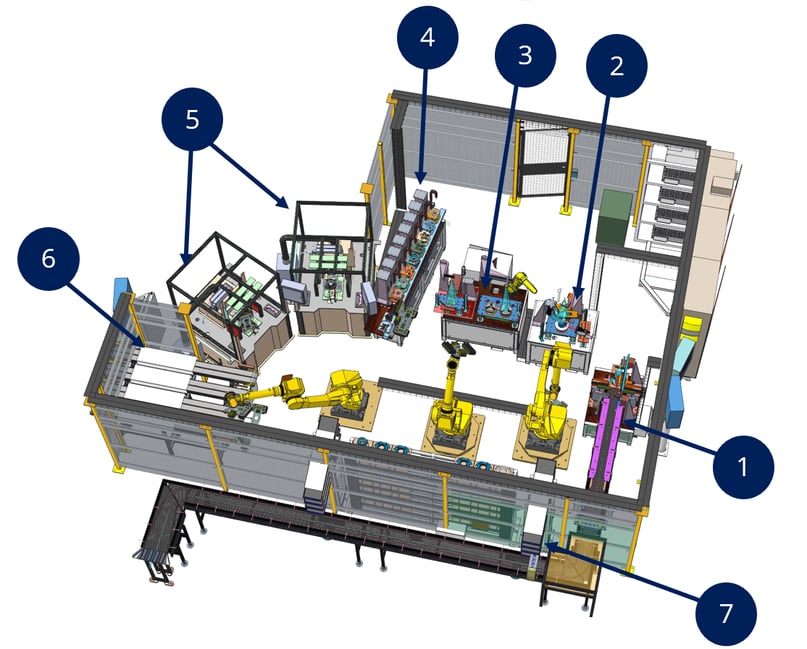

Automated quality inspection with Poka-Yoke and attribute checks verifies critical features, prevents defects and safeguards operators, delivering efficient error-proof in process inspection.End-of-Line Automated Measurement System

Challenge

The inspection process was too labor-intensive, and defective parts were getting through under the existing process. The multistage machining process requires multi-step EOL inspection. The manufactured components required a method of data acquisition and part traceability.

Process/Solution:

1. Incoming Conveyor

- Roller Conveyor

- Part Metering

- Part Orientation Control

2. Vision Inspection Station

- Inspections Include

- Hole Position

- Media Presence

- Window Heights

3. Eddy and Resonator Station

- Eddy Current Inspections

- Inner Flange Crack Depth

- Outer Flange Crack Depth

- Resonance Inspection

- Ping for Braze Condition

4. Air Gage Station

- Diameter Size Inspection

5. Laser Marking Stations

- Automatic Laser Marking

6. Exit Conveyors

- Powered Belt Conveyors

7. Reject Conveyors

- Gravity Roller Conveyors

Get Expert Insight for Your Next Metrology Automation Project

Discover the ideal automated metrology solutions for your plant.

Whether you're in early planning or ready to optimize throughput challenges, our team will assess your needs and offer recommendations built around your operation.