Automated Metrology Systems

Acieta brings Industry 4.0 to your quality control process by integrating automated quality inspection and advanced metrology equipment enabling real-time SPC, data traceability, and precision measurements without compromising throughput.

< 60 seconds

MEASUREMENT TIME PER PART

100%

IN-LINE PROCESS INSPECTION

< 1 second

FULL 360° SCANNING

10,000+

SYSTEMS INTEGRATED GLOBALLY

DIMENSIONAL MEASUREMENT

Acieta provides comprehensive automated metrology solutions for precision industries, utilizing advanced measurement technology to deliver powerful, durable systems.

EDDY CURRENT TESTING & RESONANCE TEST SYSTEMS

Acieta utilizes eddy current testing and resonance test systems to provide non-destructive inspection solutions for precision manufacturers.

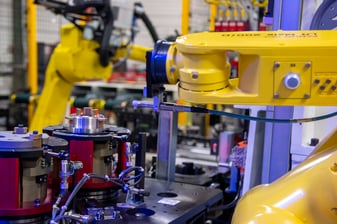

3D & 2D VISION INSPECTION SYSTEMS

Acieta offers powerful 2D and 3D robotic vision inspection systems for 100%inspection, assembly verification and other advanced metrology processes.

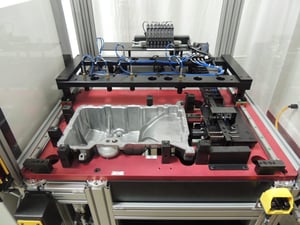

LEAK & FLOW TEST SYSTEMS

Acieta offers custom-designed solutions for automated leak and flow testing, delivering precise, easy-to-maintain systems for any application.

TOOL COMPENSATION GAGE SYSTEMS

Acieta has decades of experience developing CNC machine tending tools to maximize efficiency, and provide unmatched process control.

VIRTUAL CONDITION & ATTRIBUTE INSPECTION

Acieta provides integrated error-proofing tools to ensure both operator throughout , and verification of process-critical features.High-Speed In Process Inspection for Small Parts

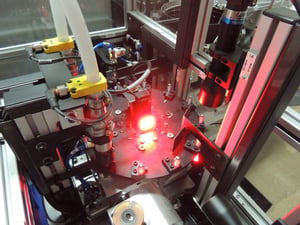

Challenge

A manufacturer of bushings needed 100% inline quality control with sub-second cycle times.

Multiple bushing sizes required frequent changeovers for dimensional checks, surface defect detection, and groove width measurement, creating downtime and potential quality risks

Acieta’s Solution

- Built a custom automated metrology system featuring high-speed rotary servos and 3D vision metrology equipment.

- Enabled full 360° in process inspection, providing complete inline quality control in under one second.

- Designed an quick-change tooling plate, reducing diameter adjustments to under 15 minutes and minimizing production downtime.

Results

- Sub-Second, Automated Quality Inspection for each bushing

- Rapid Changeover support flexible production and eliminate downtime without sacrificing throughput

- Consistent, Automated Measurements improve quality assurance across high-volume runs.

- Metrology Automation replaces manual operation with scalable, in process inspection

Get Expert Insight for Your Next Metrology Automation Project

Discover the ideal automated metrology solutions for your plant.

Whether you're in early planning or ready to optimize throughput challenges, our team will assess your needs and offer recommendations built around your operation.