Robotic Welding Systems

Trusted by leading manufacturers in automotive, aerospace, agriculture, construction, heavy equipment, and metal fabrication, Acieta designs and integrates fully automated welding systems to meet demanding production goals with consistency and efficiency.

2-3x

AVERAGE INCREASE IN THROUGHPUT

20-25%

REDUCTION IN WELD DEFECTS

100%

WELD TRACEABILITY AND INTEGRATED QA

10,000+

SYSTEMS INTEGRATED GLOBALLY BY ACIETA

Experts in Multi-Industry Manufacturing

As expert robotic welding system integrators, we design and build custom robotic welding systems for industrial manufacturers seeking greater throughput, consistency, and quality.

From agriculture and construction equipment to automotive and aerospace components, Acieta helps manufacturers reduce rework, increase uptime, and scale efficiently with robotic weld cells purpose-built for their operations.

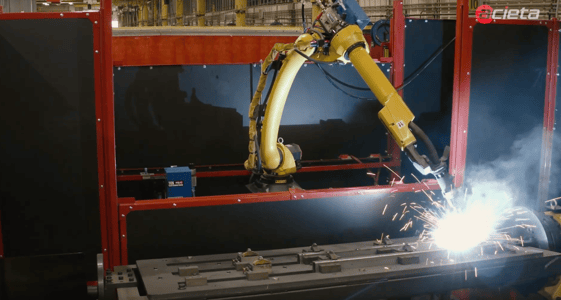

AUTOMATED MIG WELDING

A robotic MIG welder delivers versatility for joining materials across a wide range of thicknesses, from thin sheet metal to heavy plate. With automated MIG welding, manufacturers achieve cleaner cosmetic welds, consistent quality, and flexibility in both fixtured and fixtureless setups.

Ideal for: thin to heavy material thickness, cosmetic welds, both fixtured and fixtureless setups

Materials: carbon steel, stainless steel, and aluminum

AUTOMATED SPOT WELDING

A robotic spot welder provides manufacturers with a fast, reliable way to join thin materials with minimal distortion, making it a cost-effective solution for high-volume production. With automated spot welding, companies gain consistent quality, reduced cycle times, and improved efficiency.

Ideal for: thin material joining with minimal distortion, fast, high-throughput applications, and suitable for repetitive high-volume production

Materials: carbon steel, stainless steel

Built to Work & Scale With Your Equipment

CUSTOMIZABLE FEATURES ACROSS ALL SYSTEMS:

- Fume extraction for cleaner environments

- Touch sensing and seam tracking for precision

- Tailored fixturing for your parts

- Pre-heat capability for improved weld quality and reduced defects

COMPATIBLE WITH:

- Lincoln Electric

- Miller

- Fronius

- Customer-specified equipment

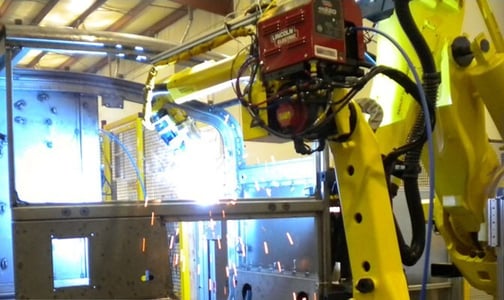

A Trailer Manufacturer’s Success with Robotic MIG Welding

A reliable welding process is the key differentiator between on-time delivery and costly delays or damage. Acieta is trusted by 70% of the top trailer manufacturers including those specializing in flatbeds, refrigerated and dump trailers, utility and specialty trailers, motorhomes, and RVs.

A leading trailer manufacturer turned to Acieta for automated MIG welding solutions.

By integrating FANUC vision technology to identify precise welding areas, the mig welding robot can accurately move to each spot without manual handling ensuring greater safety, consistency and precision in each weld.

Our systems empower industry leaders build stronger, lighter trailers improving quality and reducing costs without compromise.

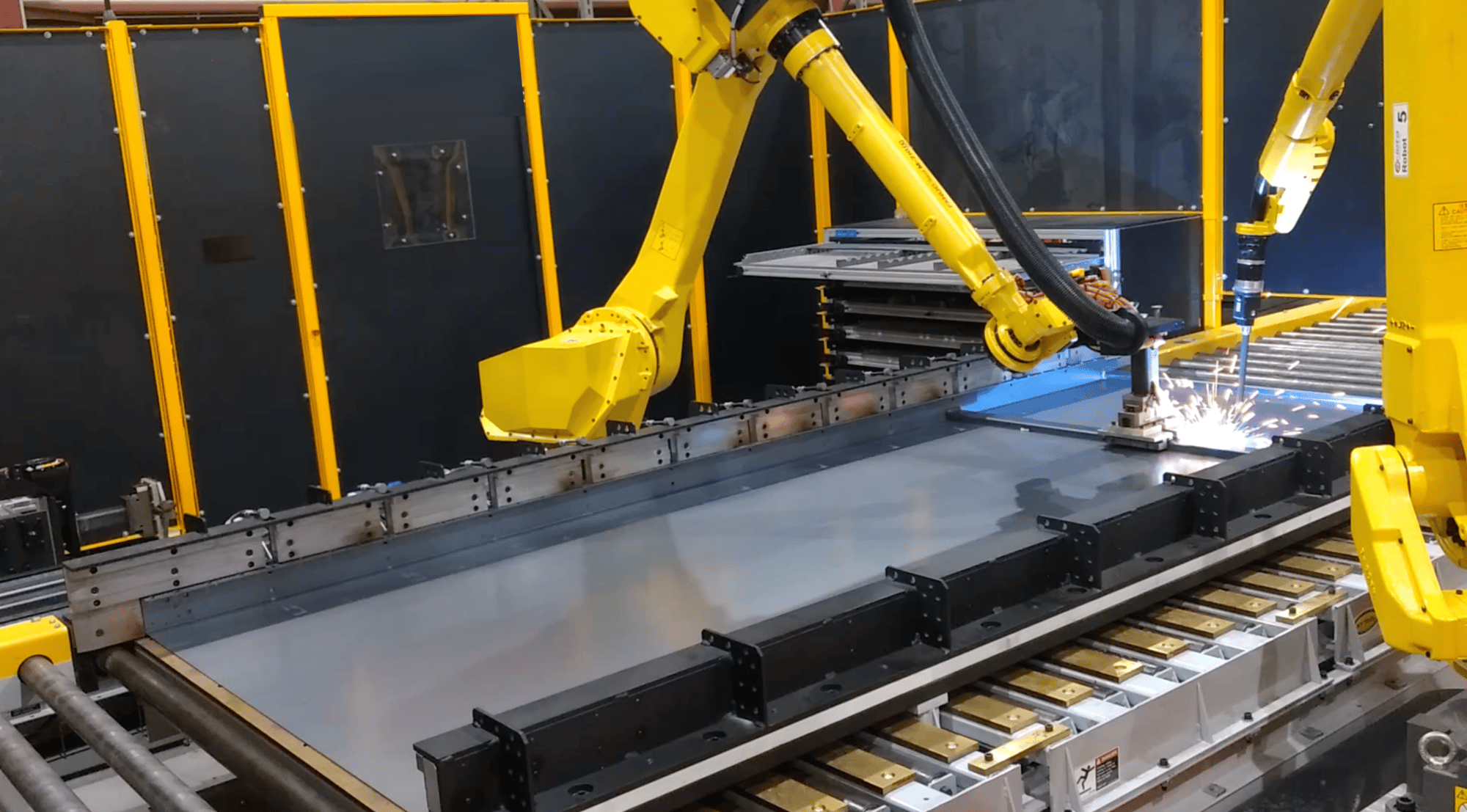

Beyond the Arc: Bending, Tending & more

When a part requires both welding and bending, automating just one step can create bottlenecks in the production line.

That’s why we go beyond core processes to integrate secondary operations like bending, machine tending, pick and place, material handling and more ensuring a seamless transition from one stage to the next.

Whether you're working with raw steel, aluminum, tubing, or finished components, we design systems that streamline the entire workflow.

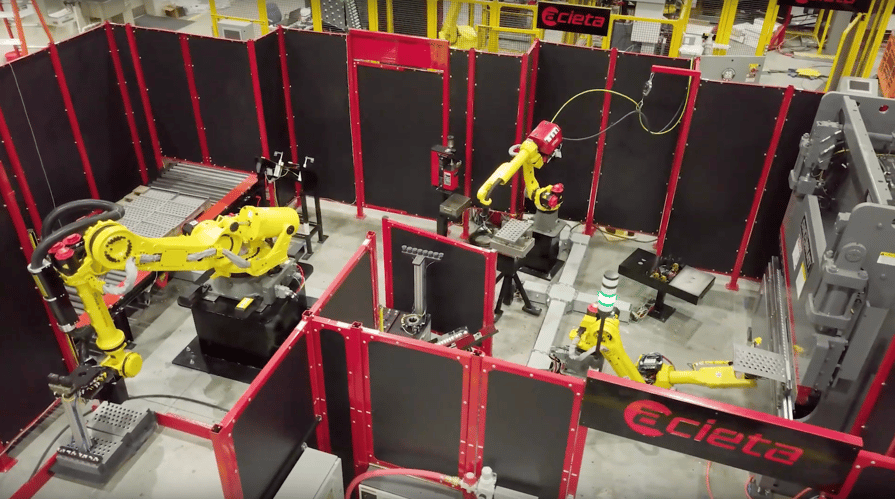

Why Choose Acieta?

As an A3 Certified Robot Integrator, FANUC Authorized System Integrator and one of the top Certified Servicing Integrators, Acieta provides more than just automation.

We ensure long-term system performance and reliability.

With seven facilities across North America, we offer:

• 24/7 Technical Support & Service

• Comprehensive Training

• Certified Repairs & Warranty Service

With over 10,000 systems integrated globally, we have the experience and resources to support your automation needs now and in the future.

Get Expert Insight for Your Next Automation Project

Whether you're in early planning or ready to optimize throughput challenges, our team will assess your needs and offer recommendations built around your operation.

Fill out the form to get personalized recommendations built around your operation’s scale, complexity, goals and workflow.