Custom Case Palletizing Systems

Are you looking for automated case palletizing systems? As a FANUC Authorized System Integrator (ASI) and A3 Certified Robot Integrator, Acieta designs and integrates full range robotic case palletizing solutions built to address your most complex case palletizing challenges.

100+

CASES PER MINUTE

85%+

AVERAGE OVERALL

EQUIPMENT EFFECTIVENESS

Up to 700 kg

PAYLOAD CAPACITY

10,000+

SYSTEMS INTEGRATED GLOBALLY

Robotic Case Palletizers Engineered for Maximum Uptime

As a FANUC Authorized System Integrator with over a century of combined expertise, we deliver high-performance case palletizing systems tailor made to your needs.

Whether it's a single high-speed case palletizer or a fully automated, multi-line, mixed case palletizing system, our solutions are built to scale with your operations. We ensure consistent pattern accuracy, optimized layer stability, and maximum line efficiency—without ever compromising quality.

CASE CONVEYORS:

Ensure smooth case flow throughout the system.

- Transport empty cases to the packing area

- Carry filled cases to labeling, sealing, and palletizing stations.

-

Ability to accumulate and change elevations via spirals, incline/declines, case elevators.

ROBOTIC CASE PALLETIZER WITH VACUUM, SPATULA OR CLAMP

Delivers fast and accurate palletizing based on your product type.- Vacuum EOAT:

• Ideal for lightweight or non-porous items

• Enables faster cycle times

• Supports complex palletizing patterns - Spatula Gripper:

• Best for flat, rigid items like open-top cases when products require support from bottom during palletizing - Clamp Gripper:

• Simplifies handling of standard case patterns when vacuum picking is not possible

ADDITIONAL FEATURES & OPTIONS:

Optimized to maintain pattern accuracy, load stability and overall consistency.- Integrate with existing WMS/MES systems for tracking production data through our systems

- Pallet Dispensers automate pallet placement for continuous workflow

- Stretch Wrappers automates the wrapping process with consistent tension control and customizable wrap patterns

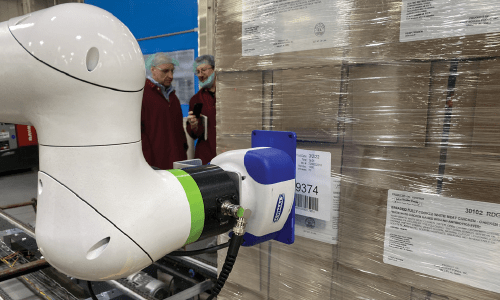

- Robotic Labeling labels cases and finished pallets, and can apply pre-printed labels or print and apply

- Barcode Readers track your products and error-proof your processes

- Dunnage System:

• Automatic handling of pallets, tier sheets, top frames, and corner boards available

• Provides load stability and prevents damage during transport

Dual-Function Robotic Palletizer for Bottles & Cases

In this video, we walk through a custom robotic palletizing solution developed for a customer who needed to upgrade their palletizing operations after making upstream changes. Their goal? A single, efficient system that could handle both bulk glass bottles and case palletizing on the same line.

Our engineering team delivered a flexible, all-in-one solution featuring:

- A 1-to-4 leaning system that splits single-file bottles into multiple lines

- A dedicated robotic sweep system that builds full pallets of bulk glass

- Integrated functionality for both bottle and case palletizing

This upgrade helped the customer improve throughput, reduce manual handling, and optimize floor space.

Why Choose Acieta?

As a FANUC Authorized System Integrator and one of the top Certified Servicing Integrators, Acieta provides more than just automation—we ensure long-term system performance and reliability.

With seven facilities across North America, we offer:

• 24/7 Technical Support & Service – Immediate assistance to minimize downtime and keep operations running.

• Comprehensive Training – Equipping your team with the skills to maintain and optimize your robotic systems as well as simplifying product changeovers.

• Certified Repairs & Warranty Service – Our FANUC-certified technicians provide fast, reliable service to keep your systems operating at peak performance.

With over 10,000 systems integrated, we have the experience and resources to support your automation needs—now and in the future.

Dual Robotic Palletizing, Tracking, Labeling & Wrapping Line with Custom EOAT

With over 150 different display cases and the need to manage four distinct pallet formats, Colbert Packaging, a leading manufacturer of corrugated packaging solutions faced significant challenges in their end-of-line packaging process. These complexities required a system capable of adapting to a mixed case palletizing system while maintaining a high throughput and minimizing manual intervention.

Together, we developed a custom robotic case palletizing system designed to address Colbert's specific operational challenges. This solution not only streamlined palletizing operations, but also incorporated end-to-end traceability, empowering Colbert Packaging to track performance in real-time and make data-driven decisions. This enhanced visibility ensures consistent quality, precision, and operational efficiency, while reducing human error.

Today, the system handles over 600 case types, providing the flexibility needed to meet the demands of an ever-evolving production environment.

We build automatic case palletizing systems for leaders in industrial manufacturing

Discover the ideal robotic case palletizer for your operations.

Whether you're planning a project or just exploring ideas, we're here to help. Fill out the form and get tailored recommendations from our subject matter experts.