Robotic Weld Cells & Press Brake Automation Systems

Acieta builds its reputation on what few can do well - welding, fabrication, and bending massive, complex parts with precision. We design and build turnkey robotic welding systems, press brakes, and the processes that surround them to streamline end-to-end fabrication in industrial manufacturing.

20-25%

REDUCTION IN WELD DEFECTS

2-3 x

AVERAGE INCREASE IN THROUGHPUT

100%

WELD TRACEABILITY AND INTEGRATED QA

10K

SYSTEMS INTEGRATED GLOBALLY BY ACIETA

Tailored Systems Built Around Your Entire Process

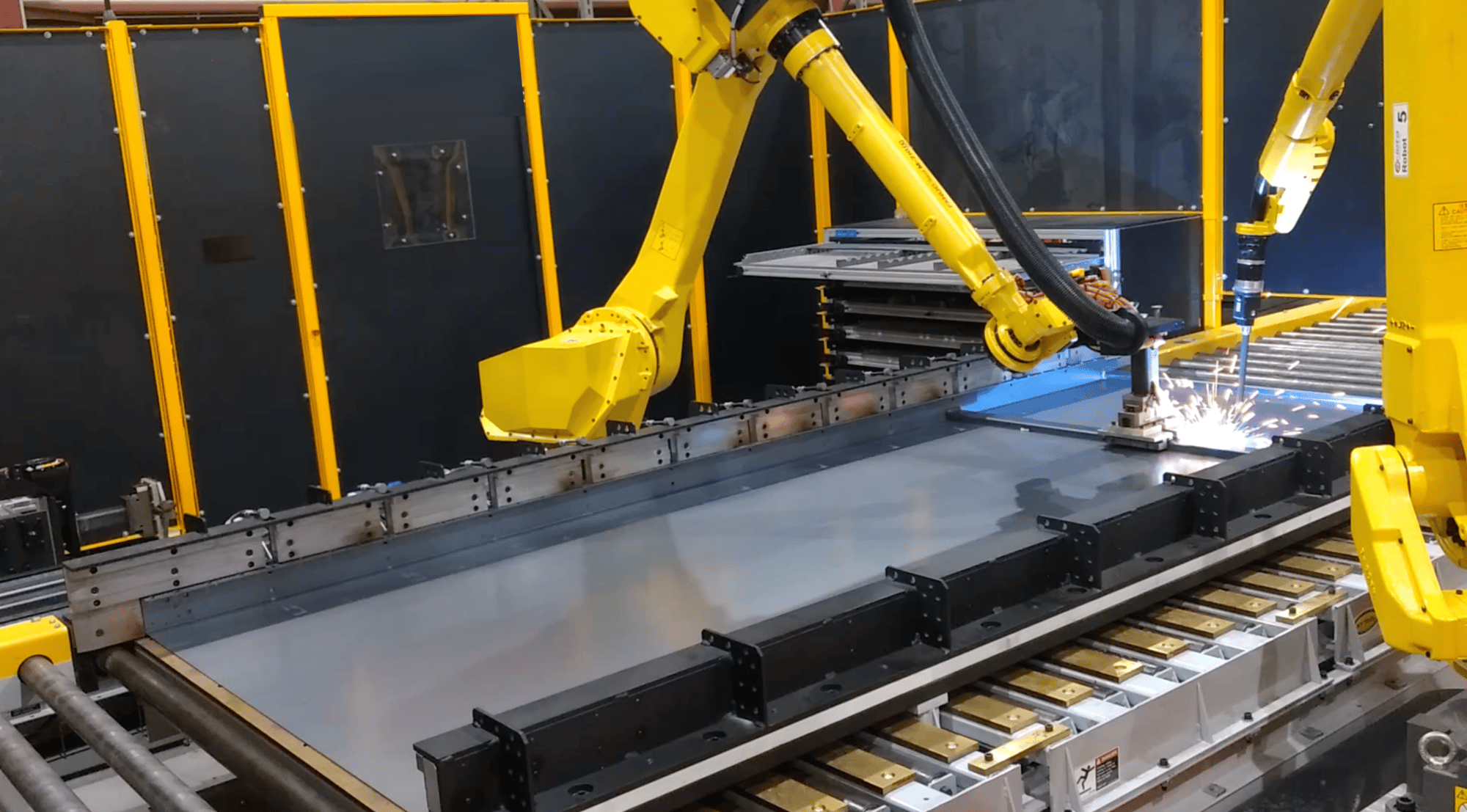

ROBOTIC WELDING SYSTEMS:

Parts and components:

boom frames, tillage tools, cabs, chassis frames, loader arms, structural supports, landing gear components + more

Robotic welding applications:

precision TIG, MIG and spot welding, thin and thick material welding, integrated secondary processes (part marking, bending, etc.)

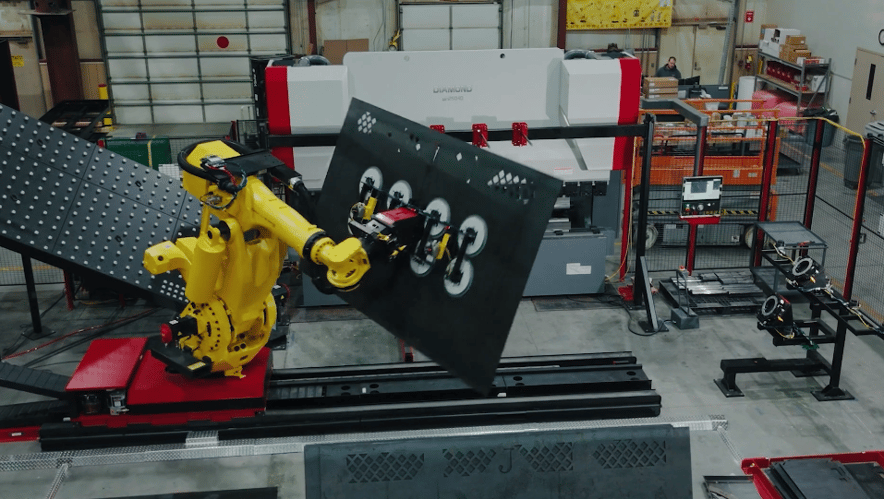

ROBOTIC PRESS BRAKE:

Parts and components:

engine mounts, structural supports, landing gear, upper couplers, utility truck bodies, scoops, skid steer components, + more

Robotic bending applications:

simple forming, special die-sets, autonomous EOAT changeover, integrated secondary processes (part marking, welding, etc.)

Beyond the Arc and the Press

Go beyond standalone cells with full-line systems purpose-built to your operations and engineered to do more, combining welding, bending, machine tending, and other processes to save time, space and labor. By unifying tasks within a single footprint, we help eliminate bottlenecks, streamline workflows, and get more from your floorspace.

Why Choose Acieta?

As an A3 Certified Robot Integrator, FANUC Authorized System Integrator and one of the top Certified Servicing Integrators, Acieta ensures long-term system performance and reliability.

With seven facilities across North America, we offer:

• 24/7 Technical Support & Service

• Comprehensive Training

• Certified Repairs & Warranty Service

With over 10,000 systems integrated globally, we have the experience and resources to support your automation needs now and in the future.

Get Expert Insight for Your Next Automation Project

Whether you're in early planning or ready to optimize your welding & press brake automation challenges, our team will assess your needs and offer recommendations built around your operation.

Fill out the form to get started.